Izigaba zama-LED anephimbo elincane zinyukile, futhi seziqalile ukuncintisana ne-DLP ne-LCD emakethe yokubonisa yasendlini. Ngokusho kwedatha esikalini semakethe yokubonisa i-LED yomhlaba wonke, kusukela ngo-2018 kuya ku-2022, izinzuzo zokusebenza zemikhiqizo yokubonisa i-LED ye-pitch encane zizobonakala, kwakheka umkhuba wokushintsha ubuchwepheshe be-LCD bendabuko kanye ne-DLP.

Ukusatshalaliswa kwemboni yamakhasimende e-LED anephimbo elincane

Eminyakeni yamuva nje, ama-LED ane-pitch encane azuze ukuthuthukiswa okusheshayo, kodwa ngenxa yezindleko nezinkinga zobuchwepheshe, okwamanje asetshenziswa kakhulu ezinkundleni zokubonisa ubuchwepheshe. Lezi zimboni azizwelani nezintengo zomkhiqizo, kodwa zidinga ikhwalithi yokubonisa ephezulu uma kuqhathaniswa, ngakho-ke zithatha ngokushesha imakethe emkhakheni wezibonisi ezikhethekile.

Ukuthuthukiswa kwama-LED anephimbo elincane kusukela emakethe ebonisiwe ezinikele kuya ezimakethe zezohwebo nezivamile. Ngemuva kuka-2018, njengoba ubuchwepheshe buvuthwa nezindleko zehla, ama-LED anephimbo elincane aqhume ezimakethe zokubonisa ezentengiso ezifana namagumbi enkomfa, imfundo, izitolo ezinkulu, namatiyetha amamuvi. Isidingo sama-LED ane-pitch encane esezingeni eliphezulu ezimakethe zaphesheya siyakhula ngesivinini. Abakhiqizi be-LED abayisikhombisa abahamba phambili emhlabeni basuka e-China, kanti abakhiqizi abayisishiyagalombili abahamba phambili benza ama-50.2% esabelo semakethe yomhlaba wonke. Ngikholwa ukuthi njengoba ubhubhane olusha luzinza, izimakethe zaphesheya zizothuthuka maduze.

Ukuqhathaniswa kwe-LED-pitch encane, i-Mini LED, ne-Micro LED

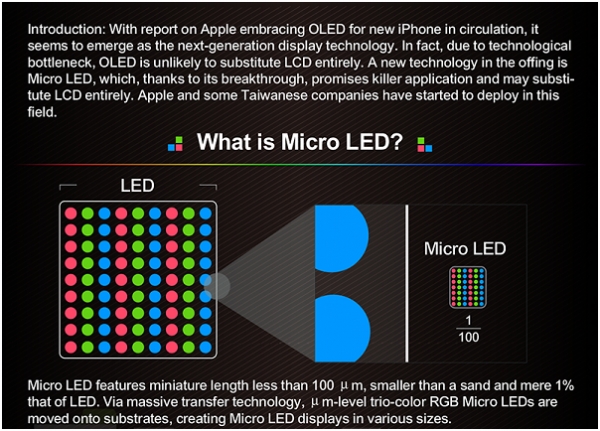

Ubuchwepheshe bokubonisa obuthathu obungenhla bonke busekelwe ezinhlayiyeni ezincane zekristalu ye-LED njengamaphoyinti akhanyayo we-pixel, umehluko usebangeni eliphakathi kobuhlalu besibani obuseduze nosayizi we-chip. I-Mini LED kanye ne-Micro LED yehlisa futhi isikhala sobuhlalu besibani nosayizi we-chip ngesisekelo sama-LED anephimbo elincane, okuyinkambiso evamile kanye nesiqondiso sokuthuthukiswa kobuchwepheshe bokuboniswa kwesikhathi esizayo.

Ngenxa yomehluko kusayizi we-chip, izinkambu zohlelo lokusebenza zobuchwepheshe obuhlukahlukene zizohluka, futhi ukuphakama kwephikseli encane kusho ibanga eliseduze lokubuka.

Ukuhlaziywa kwe-Small Pitch LED Packaging Technology

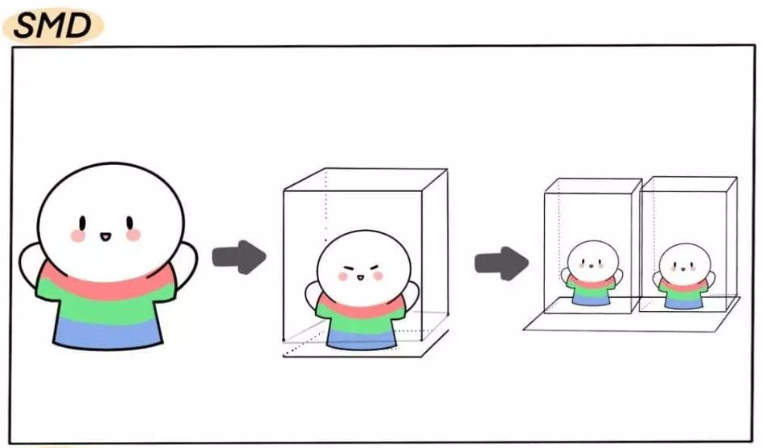

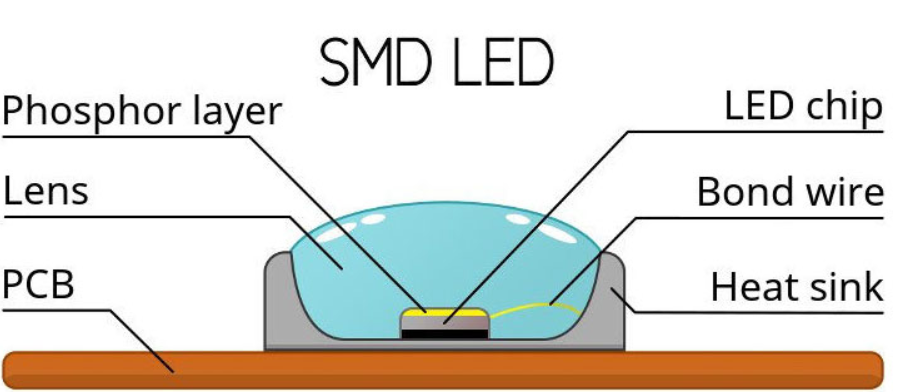

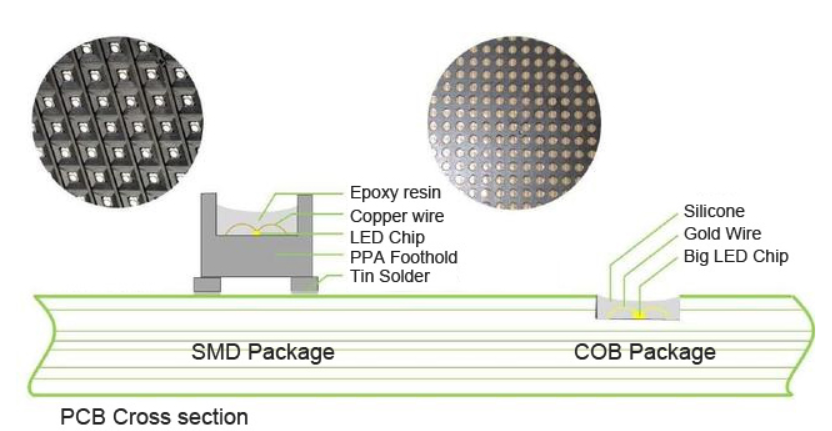

I-SMDisifinyezo sedivayisi yokukhweza ngaphezulu. I-chip engenalutho igxiliwe kubakaki, futhi uxhumano lukagesi lwenziwa phakathi kwama-electrode aqondile noma angalungile ngocingo lwensimbi. I-epoxy resin isetshenziselwa ukuvikela ubuhlalu besibani se-SMD LED. Isibani se-LED senziwe nge-reflow soldering. Ngemva kokuba ubuhlalu bushiselwe nge-PCB ukuze bakhe imojuli yeyunithi yokubonisa, imojula ifakwa ebhokisini elingaguquki, futhi ukunikezwa kwamandla, ikhadi lokulawula kanye nocingo kwengezwa ukwenza isikrini sokubonisa se-LED esiphelile.

Uma kuqhathaniswa nezinye izimo zokupakisha, izinzuzo zemikhiqizo epakishwe ye-SMD idlula ukubi, futhi ihambisana nezici zesidingo semakethe yasekhaya (ukwenza izinqumo, ukuthenga, kanye nokusetshenziswa). Futhi ziyimikhiqizo evamile embonini futhi zingathola ngokushesha izimpendulo zesevisi.

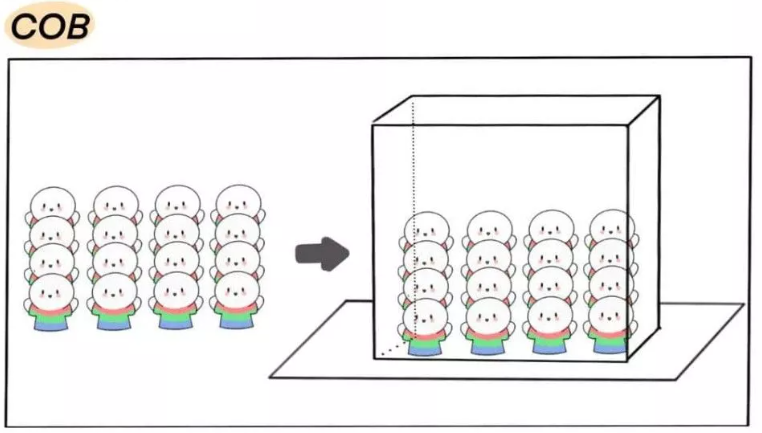

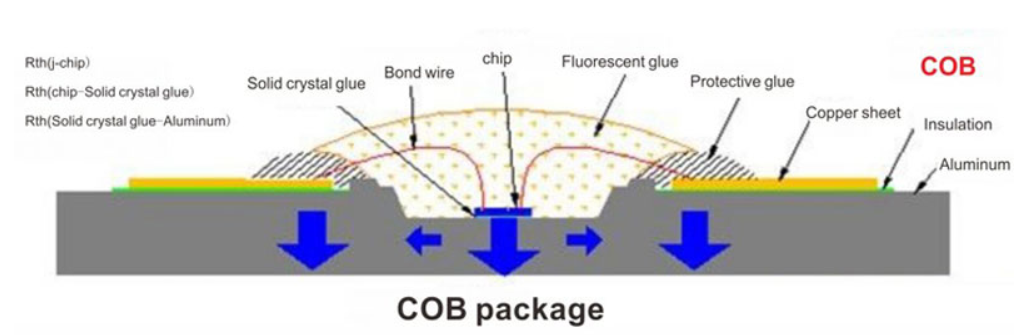

I-COBinqubo iwukunamathela ngokuqondile i-chip ye-LED ku-PCB ngeglue eqhubayo noma engaqhubeki, futhi wenze isibopho sentambo ukuze uzuze ukuxhumana kukagesi (inqubo yokukhweza enhle) noma ukusebenzisa ubuchwepheshe be-chip flip-chip (ngaphandle kwezintambo zensimbi) ukwenza okuhle nokubi. ama-electrode obuhlalu besibani axhunywe ngokuqondile ekuxhumekeni kwe-PCB (ubuchwepheshe be-flip-chip), futhi ekugcineni kwakhiwa imojula yeyunithi yokubonisa, bese imojuli ifakwa ebhokisini elingaguquki, ngokunikezwa kwamandla, ikhadi lokulawula nocingo, njll. yakha isikrini sokubonisa se-LED esiqediwe. Inzuzo yobuchwepheshe be-COB ukuthi yenza inqubo yokukhiqiza ibe lula, inciphise izindleko zomkhiqizo, inciphise ukusetshenziswa kwamandla, ngakho-ke izinga lokushisa elingaphezulu kwesibonisi liyancishiswa, futhi umehluko uthuthukiswa kakhulu. Ububi ukuthi ukwethembeka kubhekana nezinselele ezinkulu, kunzima ukulungisa isibani, futhi ukukhanya, umbala, nombala we-inki kusenzima ukwenza Ukuvumelana.

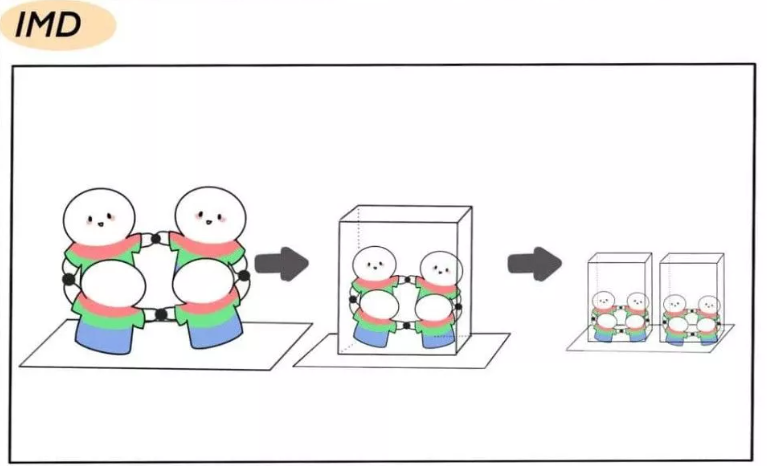

I-IMDihlanganisa ama-N amaqembu obuhlalu besibani se-RGB abe yiyunithi encane ukwenza ubuhlalu besibani. Umzila oyinhloko wezobuchwepheshe: I-Common Yang 4 ku-1, i-Common Yin 2 ku-1, i-Common Yin 4 ku-1, i-Common Yin 6 ku-1, njll. Inzuzo yayo isezinhlelweni zokupakishwa okuhlanganisiwe. Ubukhulu bobuhlalu besibani bukhulu, ukukhweza okungaphezulu kulula, futhi i-pitch yechashazi encane ingafinyelelwa, okunciphisa ubunzima bokulungisa. Ububi bayo ukuthi uchungechunge lwamanje lwezimboni aluphelele, intengo iphakeme, futhi ukwethembeka kubhekene nezinselele ezinkulu. Ukunakekela akulungile, futhi ukuhambisana kokukhanya, umbala, nombala uyinki akukaxazululwa futhi kudinga ukuthuthukiswa nakakhulu.

I-Micro LEDiwukudlulisa inani elikhulu lamakheli lisuka kuhlelo lwendabuko lwe-LED kanye ne-miniaturization liyise endaweni engaphansi yesekethe ukuze kwakhiwe ama-LED aphezulu-fine-pitch. Ubude be-LED yezinga lemilimitha buphinde buncishiswe kuzinga le-micron ukuze kuzuzwe amaphikseli aphezulu kakhulu kanye nokulungiswa okuphezulu kakhulu. Ngokombono, ingashintshwa ukuze ibe nosayizi abahlukahlukene besikrini. Njengamanje, ubuchwepheshe obubalulekile ebhodleleni le-Micro LED ukugqekeza ubuchwepheshe benqubo ye-miniaturization kanye nobuchwepheshe bokudlulisa ngobuningi. Okwesibili, ubuchwepheshe bokudluliswa kwefilimu emincane bungadlula umkhawulo kasayizi futhi buqedele ukudluliswa kwenqwaba, okulindeleke ukuthi kunciphise izindleko.

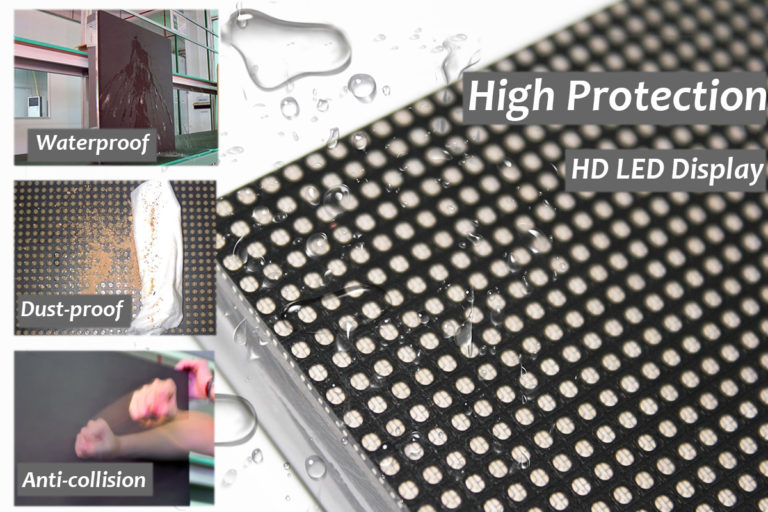

I-GOBubuchwepheshe bokumboza yonke indawo yamamojula angaphezulu. Ihlanganisa ungqimba lwe-colloid ebonakalayo ebusweni bamamojula we-SMD amancane we-SMD ukuxazulula inkinga yokuma okuqinile nokuvikelwa. Empeleni, kusengumkhiqizo omncane we-SMD. Inzuzo yayo ukunciphisa izibani ezifile. Kwenyusa amandla okulwa nokushaqeka kanye nokuvikelwa kwendawo yobuhlalu besibani. Ukungalungi kwayo ukuthi kunzima ukulungisa isibani, ukuguqulwa kwemodyuli okubangelwa ukucindezeleka kwe-colloidal, i-reflection, i-degumming yendawo, i-colloidal discoloration, kanye nokulungiswa okunzima kwe-welding virtual.

Isikhathi sokuthumela: Jun-16-2021